4 Real-World Sintered Stainless Steel Applications

Powder metallurgy (PM) has long been used to mass-produce durable stainless steel parts with complex shapes – and for go …

Stainless Steel Sintered Metal Design Guide for Engineers

Powder metallurgy is an increasingly popular option in stainless steel manufacturing. It checks three main boxes for eng …

Stainless Steel Powder Metal Parts: A Comprehensive Guide

Want to pack a 1-2-3 punch with stainless steel powder metal component design?

Understanding Sintered Stainless Steel Corrosion Resistance: Key Factors & Benefits

The sintering process is a step where a material is heated almost to the point of liquefaction, leading to the diffusion …

The Benefits of High-Temperature Stainless Steel Sintering

The conventional stainless steel sintering process involves heating a part just below its melting point – typically at t …

Understanding the Environmental Impact of Additive Manufacturing

Increase efficiency. Raise profits. Become sustainable.

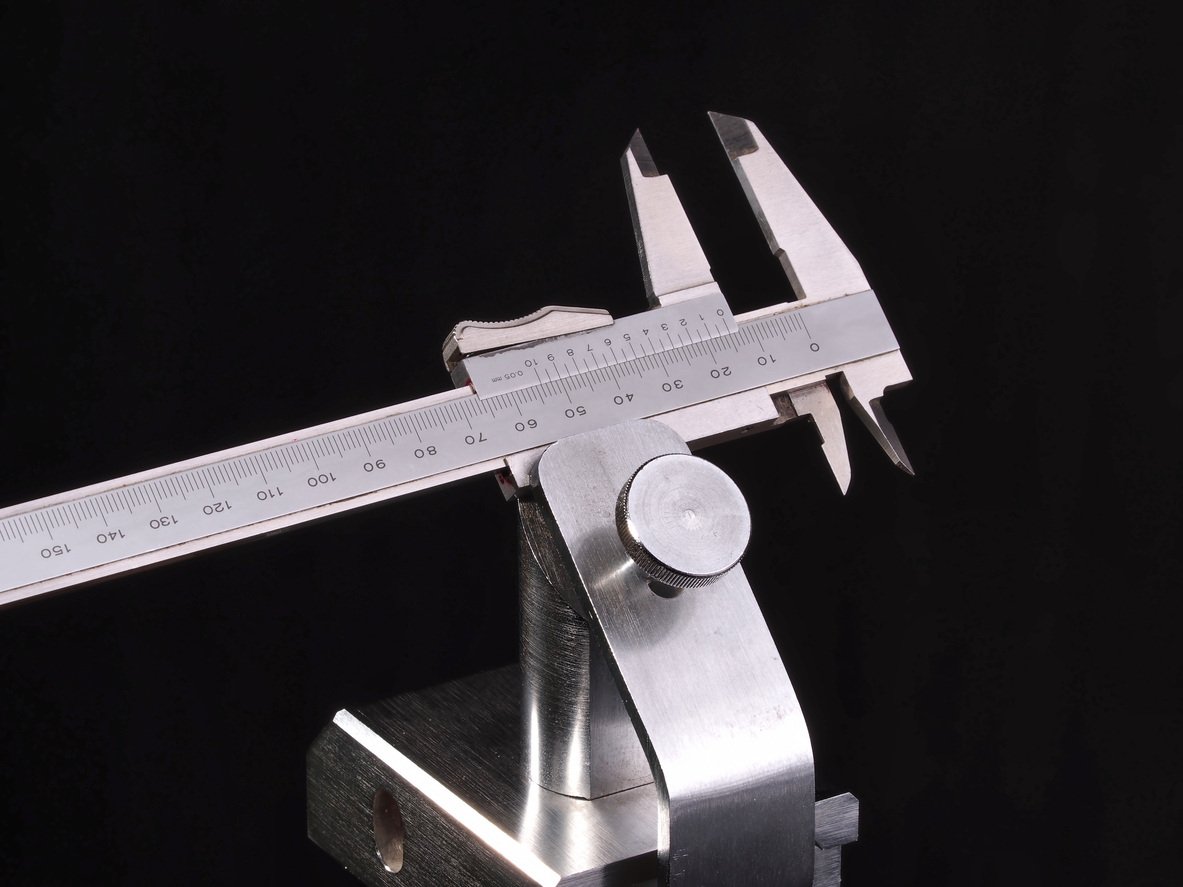

What Engineers Need to Know About Tolerances and Dimensional Control in Stainless Steel Sintering

Regarding precision components, a part is only as good as its tolerances. In stainless steel sintering, dimensional cont …

Filtration Systems and Porous Stainless Steel: Expanding the Possibilities of Sintered Metal Filters

When it comes to industrial filtration, the materials you choose can make all the difference. In recent years, sintered …

Custom Check Valves 101: Tailored Solutions for Improved System Performance

When it comes to achieving peak system performance, every detail matters—especially in engineering and manufacturing.

The Role of Low-Pressure Pumps in Fuel Injection Systems

In modern engines, fuel delivery is essential. Fuel injection systems are the foundation of engines and provide enhanced …

.png)

.jpg)

.jpg)