4 Real-World Sintered Stainless Steel Applications

Powder metallurgy (PM) has long been used to mass-produce durable stainless steel parts with complex shapes – and for go …

Stainless Steel Sintered Metal Design Guide for Engineers

Powder metallurgy is an increasingly popular option in stainless steel manufacturing. It checks three main boxes for eng …

Stainless Steel Powder Metal Parts: A Comprehensive Guide

Want to pack a 1-2-3 punch with stainless steel powder metal component design?

How Stainless Steel Sintering Reduces Material Waste and Enhances Sustainability

The sustainability of powder metallurgy (PM) is becoming more widely recognized in the industry. This additive manufactu …

The Benefits of High-Temperature Stainless Steel Sintering

The conventional stainless steel sintering process involves heating a part just below its melting point – typically at t …

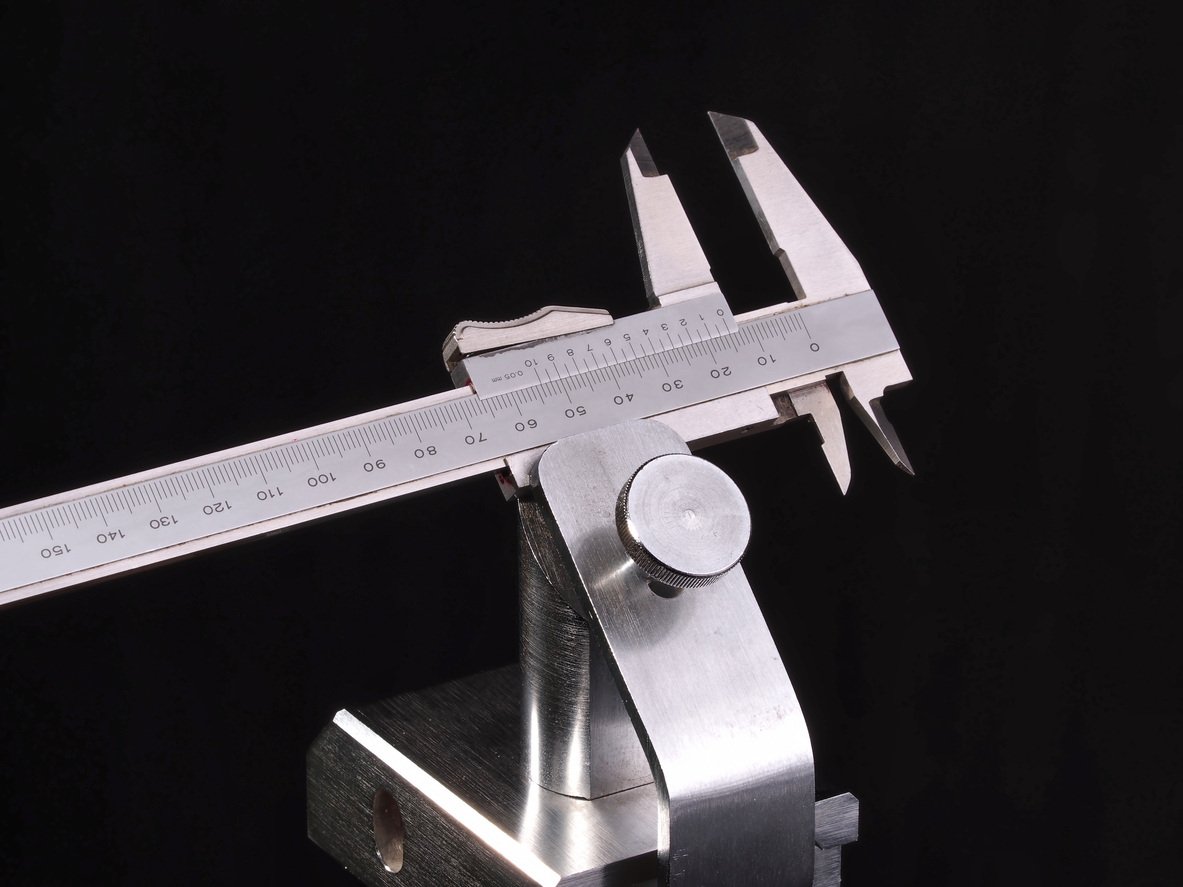

What Engineers Need to Know About Tolerances and Dimensional Control in Stainless Steel Sintering

Regarding precision components, a part is only as good as its tolerances. In stainless steel sintering, dimensional cont …

Filtration Systems and Porous Stainless Steel: Expanding the Possibilities of Sintered Metal Filters

When it comes to industrial filtration, the materials you choose can make all the difference. In recent years, sintered …

What to Look for in a Powdered Metal Parts Manufacturer

As an engineer, you know the frustration of balancing tight project deadlines with the need for top-notch component qual …

Powder Metallurgy Sintering vs. Metal Injection Molding Sintering: An In-Depth Comparison

No matter the manufacturing method, sintering follows a fundamental process. Heat is applied to the material until it’s …

The Metal Injection Molding Process: A Comprehensive Guide

Plastic injection molding offers incredible design flexibility.

.png)